durable injection plastic mould custom made injection plastic chair mold manufacturer

Basic Info

Model No.: Customized

Product Description

JMT MOULD Description:

JMT MOULD Speicification:

| Mould Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#,45# etc |

| Product Material | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS etc |

| Cavity No. | Single or multi |

| System Of Runner | Hot runner,Cold runner,Pin-point gate,Submarine gate, etc |

| Ejector Type | Ejector pin,Air gate,Ejector plate,Hydro-cylinder,etc |

| Term Of Mould Production | 35days- 60days |

| Guaranteed Number Of Cycles | 500,000-1,000,000 |

| Mould Design Software | Ug,Proe,Solidworks AotoCAD,Moldflow,ect |

JMT MOULD Process

| 1 | Product Design | Customer sends us the product drawing directly or we draw the product according to the sample,then we send customer the product drawing to confirm |

| 2 | Mould Design | We'll start to design mould after the product drawing confirmed,then send customer the mould drawing to confirm |

| 3 | Mould Making | The mould will be made after the mould drawing being confirmed,the process include steel material preparing,CNC, EDM, WEDM,polishing, accembling,etc |

| 4 | Mould Test | Mould will be tested after mould assembly,then we'll send customer samples and video of mould testing to confirm |

| 5 | Final Process | The mould start to polish if the sample is ok,and make grain,nitridation or chroming if customer required |

| 6 | Mould Test | We'll test the mould again after polishing,then send customer the final sample and video of mould test to confirm |

| 7 | Mould Packing | The mould will be packed with wooden case after the final sample confirmed |

eample

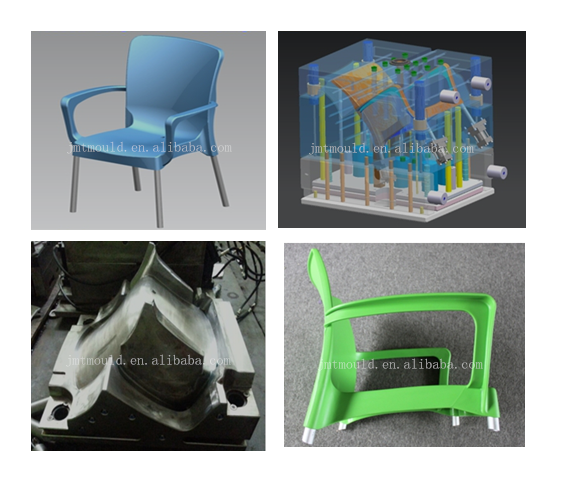

Products detail

Name | plastic Injection Chair Mould |

Main cavity material | P20 |

Mould base standard | chinese brand |

Mould cavity quantities | 1cavity |

Mould size | 1200*1121*768mm |

Mould weight | 4728kgs |

Products material | pp |

Product weight | 2.9kgs |

Payment | T/T |

Price term | FOB Ningbo, China |

Packing

Connect information

JMT Mould Quality Control

1.Mould Material Q/C

a) Mould Steel checking (hardness,flaw detection)

b) mould spare parts checking (hardness,size

2.Mould Making Process Q/C

a) design checking ( part design,mould desig,mould enginering drawing)

b) mould size checking (according to drawing)

c) mould testing (check mould working,sample)

Attention pls:

Pease offer the following information when you send us the mould inquiry

a) product drawing or the sample photo with sizes.

b) mould steel you want to use.

c) standard mould base or not.

d) runner system you want(cold or hot)

Product Categories : Commodity Mould > Other Commodity Mould

Premium Related Products