auto plastic injection mould New Car door inner panel plastic mould,auto panel mould

Basic Info

Model No.: JMT-Y0002

Product Description

We can make all kinds of plastic mould based on customer's drawing

or sample.

JMT mould has strict quality control system and high efficiency work team.

We specialize in manufacturing

plastic injection mould which covers a great range, including commodity,

household appliances, auto parts,

baby products, garden products & customized parts.

We set up perfect CAD/CAM/CAE system, We own a whole set of advanced mould

processing system,good equipment and

professional workers. We wish to provide the best service at all times at minimum cost

which is the guiding Motto of the company.

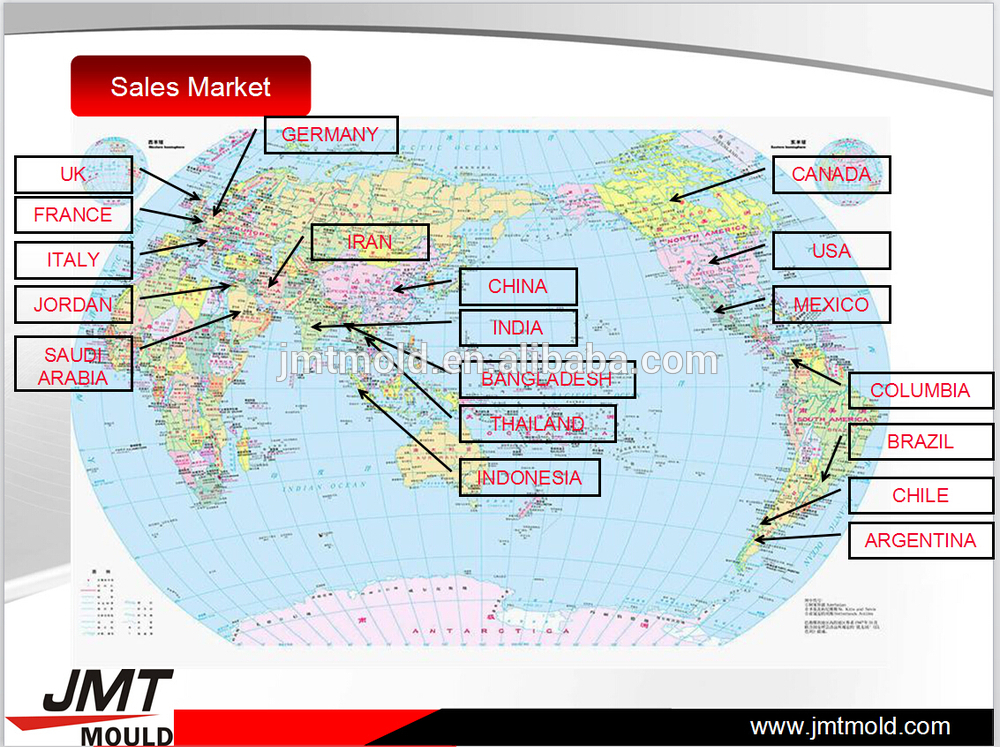

Be confident with our quality, service and price, we keep long term business relation

with our clients from Italy, UK, Germany, France, USA, Mexico, Brazil, Argentina, India,

Indonesia, Bengal and so on. Last year's output is 3 million US dollar.

Mould material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

Runner | Cold runner. Hot runner: Yudo/DME/HASCO |

Machine | 80-1600T |

Standard | HASCO, DME, LKM |

Specification drawings | Pro/E, Auto CAD, Solidwork, CAXA UG, CAD/CAM/CAE. |

Precision machining | CNC, milling machine, drilling machine, numerical lathe, all types of lathe |

Surface finish process | polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing . |

Shaping mould | injection mould |

Mould life | above 500000-1000000 shots and up |

Service | OEM service available, good after-sales service . |

Lead time | 4-7 weeks, 40 days or according to the real situation . |

Plastic material | PP, ABS, HDPE, PC, PVC ect |

JMT-Mould Trade Process :

1.Quote | According to sample, drawing and specific requirement. |

↓ | |

2.Discussion | Mold material, cavity number, price, runner, payment, etc. |

↓ | |

3.S/C Signature | Approval for all the items |

↓ | |

4. Advance | Pay 50% by T/T |

↓ | |

5.Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

↓ | |

5.Mould Design | We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

↓ | |

6.Mold Tooling | We start to make mold after mold design confirmed |

↓ | |

7.Mold Processing | Send report to customer once each week |

↓ | |

8.Mold Testing | Send trial samples and try-out report to customer for confirmation |

↓ | |

9. Mold Modification | According to customer’s feedback |

↓ |

|

10.Balance settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

↓ |

|

11.Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

wooden case

Any question ,pls feel free to contact Yearnie

Contact us if you need more details on Car Door Inner Panel Plastic Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Auto Panel Mould、Car Plastic Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Auto Parts Mould > Auto Interior Trim Mould

Premium Related Products